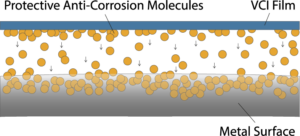

VCI is a corrosion inhibitor that we include in our packaging materials for extra corrosion protection where this is requested. The packaging material will continuously release VCI molecules that form a protective layer on the metal surface of the goods.

VCI is invisible, odorless, non-toxic and non-flammable and thus perfectly safe for your staff to handle. It does not contain nitrites and will not leave any residue on the metal surface. Packages can be opened and resealed without affecting the corrosion protection.

Use wrapping materials with VCI when shipping by sea and in climates or environments that increase the risk of corrosion.

The main factor that drives corrosion on metal is moisture, temperature and pollution. Good packaging practices will reduce the inclusion of moisture and pollution. By using machine wrapping as a standard packaging method you get a tight wrapping, with less moisture inside, compared to traditional manual packing.

During export through different climate zones and during the winter, problems with condensating water can increase. By using a quality anti-corrosion film and a high-quality wrapping machine, you can reduce the risk for corrosion to a minimum level.

Use additional packaging material to secure that the film layer is not damaged and the corrosion-protected environment gets compromised.

Contact us to set up a meeting to learn more about residue-free and long-lasting corrosion protection with VCI.

Our heavy-duty stretchfilm is intended for automated wrapping of steel or aluminum coils or bundles of pipes or bars. They are available with different types of reinforcement and with or without corrosion protection additives.

Lamiwrap is a combination of woven PP plastic and craft paper that is your optimal solution for manual wrapping of coils or sheet steel. If you require extra protection against corrosion, select the version with VCI added.

Leave your phone number and a local packaging expert will call you to discuss your needs.

See customer cases and learn the latest by following Lamiflex on LinkedIn.