Switch from virgin plastic raw materials to PCR plastic! PCR plastic is plastic that was already used in a product, then recycled to become a recycled plastic raw material. Not only is this a way to keep plastic waste from ending up in the ocean, but it is also a way to limit CO₂ emissions and to use our natural resources wisely.

Burning plastics, even to produce energy, releases large amounts of CO₂. 53% of CO₂ emissions from fossil polyethylene (PE) come from burning it at the end of a product’s lifecycle. Recycling PE as a raw material, on the other hand, requires little energy and ensures a closed material loop with both short and long-term benefits.

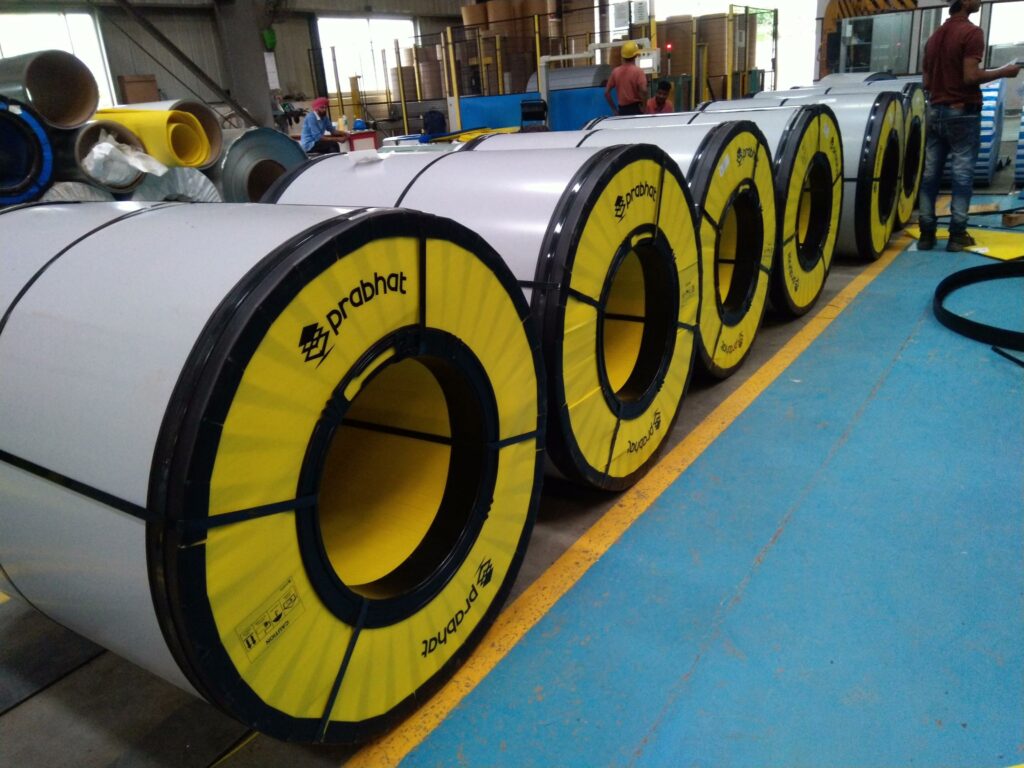

At Lamiflex we are continuously increasing the rate of PCR in our products.

To learn more about our products, manufacturing and recycling concept, please contact the Lamiflex representative in your country or region.