Coil packaging for different modes of transportation

Marcus Schröder

Steel coils are valuable, heavy and roll-prone cargo. Your customer expects to use every kilogram of steel in their production. That requires adequate coil packaging that protects the coil during transport and storage. Done well, packaging protects product integrity, reduces claims, and upholds customer satisfaction.

Understanding coil vulnerabilities

Steel coils face three primary risks in transit and during storage:

- Corrosion from humidity, condensation, salt spray or temperature cycling.

- Mechanical damage from dents, edge deformation and abrasion during lifting, loading or storage.

- Instability – coils can roll or shift if not properly blocked or strapped in place.

Best practices for protective packaging vary depending on transport distance, time between manufacturing and use, the need for unloading and reloading due to multiple transport modes, or use of intermediate storage or consignment stocks.

Common packaging practices include stretch-film wrapping with corrosion-protective additives (VCI), use of coil edge protectors and coil side and mantle protection.

Local transportation

Typical profile: The coil is transported from the mill to a service center or warehouse, or directly to a customer in proximity to the production site. The time in transit is limited, often one single mode of transport (usually truck transport) is used, and the ambient temperature and humidity will stay roughly the same.

Packaging objectives

-

- Provide basic moisture protection (protects from light rain during outdoors loading/unloading).

-

- Protect the coil from corrosion if the weather conditions are unpredictable, or in case storage times become longer than planned. This is especially important in consignment stock.

-

- Protect against mechanical damage to the coil surface or coil edges during handling.

Recommended minimum packaging

-

- Stretchfilm wrapping (reinforced if needed), possibly with VCI (depending on product to be packed)

-

- Inner edge protection (in the eye) + plastic strapping

Why it works

Stretchfilm protects the coil from corrosion and acts as basic weather protection during loading operations outdoors. The wrapping should be tight and through the eye for minimal air inclusion to avoid corrosion. Stretchfilm with VCI is a great insurance against corrosion.

To remain effective over time the wrap needs to stay intact and without rips or holes during both transit and storage.

The inner edge protection serves three purposes:

- It protects coil edges from damage from lifting devices, such as forklifts, coil rams, crane hooks, chains or slings.

- It also protects the stretchfilm from ripping at the edges when the coil is lifted. This type of damage may otherwise occur even with padded lifting devices.

- It ensures that the straps that secure the coil during transport do not chafe against the sharp coil edges and rip apart.

The edge protection can be secured with steel or plastic straps.

Long distance transportation

Typical profile: Transportation by truck, train or canal boats (Europe) over the course of days up to a few weeks. Unloading and reloading is likely to occur more often due to use of more than one transport mode, or intermediate storage. There is added weather exposure and/or temperature swings.

Packaging objectives

-

- Increase corrosion protection to withstand added weather exposure and condensation cycles.

-

- Reinforce impact resistance for handling at multiple nodes, sometimes by third party personnel.

Recommended minimum packaging

-

- Reinforced stretchfilm wrapping with VCI, applied with larger overlap. If coil edges are sharp, use protectors at the coil edges to avoid damage to stretchfilm.

-

- Inner and outer diameter edge protection (eye + mantle) + plastic or steel straps.

Why it works

Plastic stretchfilm with VCI protects against corrosion and with reinforcements it is less likely to be damaged. An increased overlap improves the sealing of the coil.

Placing protectors over the coil edges minimizes the risk that the stretchfilm breaks due to abrasion against the sharp steel edges during loading and handling. Keeping the stretchfilm intact is crucial to maintain VCI effectiveness.

Inner and outer diameter edge protection protects the parts of the coil that are most likely to sustain impact damage during handling, transport and storage. Inner diameter edge protection also protects straps used to secure the coil from chafing.

Export transportation

Profile: Several weeks in transit, often intercontinental shipping, using multiple transport methods with an added number of loading and unloading points. Temperature swings, possible saltwater exposure or container humidity threats.

Packaging objectives

-

- Best possible corrosion protection.

-

- Reinforced impact resistance for handling at multiple nodes by third parties with varying familiarity with your goods.

-

- Packaging that will sustain prolonged exposure to both moisture and vibrations.

Recommended packaging

-

- Reinforced, solid stretchfilm wrapping with VCI. If coil edges are sharp, use protectors at the coil edges to avoid damage to stretchfilm.

-

- Inner and outer diameter edge protection (eye + mantle/side).

-

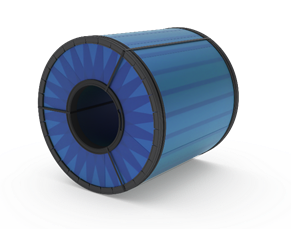

- Plastic coil body protection over the coil mantle, side and inside the eye.

-

- Steel straps with metal closures.

Why it works

VCI is effective for preventing corrosion even during long transits. Keeping the stretchfilm protected from chafing when using lifting devices ensures VCI effectiveness over time.

Plastic edge protection in combination with plastic coil side and mantle protection provides protection from mechanical impact from additional loading and offloading operations. It stays intact even in moist or wet conditions.

Steel straps keep the coil edge and body protection in place. They are impact resistant and the steel closures remain secure even when subject to prolonged vibration.

Overview

| Objective | Local transport | Long distance | Export |

|---|---|---|---|

| Corrosion defence | Stretchfilm wrapping with VCI | Reinforced stretchfilm wrapping with VCI | Reinforced stretchfilm wrapping with VCI |

| Impact protection | Edge guards in the eye | Edge guards in the eye + on the outer diameter | Edge guards in the eye + on the outer diameter, plastic shock.absorbent body protection, straps with steel closures |

|

|

|

Mistakes to avoid

- Underpackaging. The longer the transport route, the more costly and time-consuming it will be to replace a damaged product – not accounting for the dissatisfaction and damage to your reputation that occurs if your customer receives damaged goods.

- Repairing damaged stretchfilm with plastic tape before shipping. The VCI may already be depleted. Manual repairs are also time-consuming and there is a risk of missing additional holes or insufficient repairs. It is better to re-wrap the coil before shipping to ensure proper corrosion protection.

- Using low-tension or low-sealing stretchfilm, film that does not seal properly, or a too narrow overlap when wrapping. Any of the above can result in insufficient sealing of the coil, disturbing the efficiency of the corrosion protection.

- Using packaging materials that are not resistant to moisture, such as hardboard, which will lose its structural integrity when exposed to water/moisture.

Sustainability & recycling considerations

The European Union is continuously pushing for a higher level of recycling, with added taxes or fees on products that are made from virgin materials or products that make recycling more difficult. It is advisable – and more sustainable – for anyone inside, or exporting to the EU, to use monoproduct packaging instead of composites.

Composite materials like kraft paper with a plastic layer cannot be recycled for material recovery. If the properties of plastic is needed it is better to use packaging products made from 100% plastic that can easily be recycled and then used to manufacture new products.